| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Shengli |

| Model Number : | LHY |

| Certification : | CE and ISO |

| Price : | Negotiable |

| Supply Ability : | 200-300 SET PER MONTH |

| Delivery Time : | 1 MONTH |

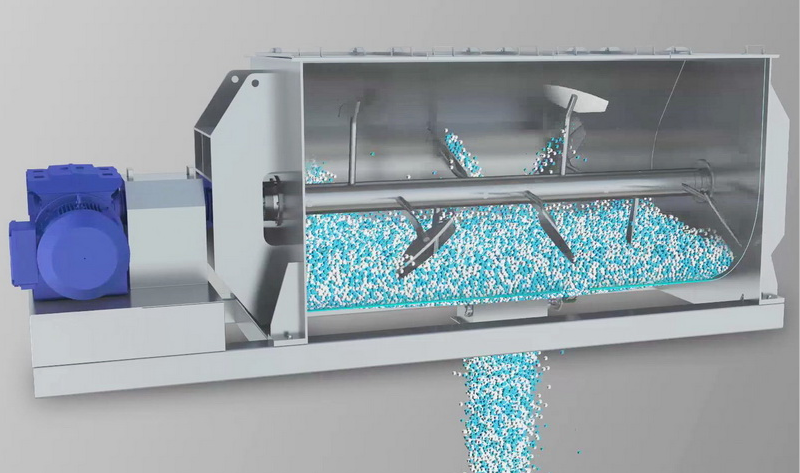

Easy Operation Industrial Food Paddle Mixer For Chocolate / Ice Cream

Paddle blender is widely applied in food, daily chemical,

biological, and fermentation area.

It can mix wet powder, sludge-like material or paste in battery,

construction, environmental, mineral and agricultural line, wet

material blending,or dry powder material mixing.

Paste blender, paste mixer, chocolate blender,chocolate mixer, ice cream blender, ice cream mixer, blender for powders.

1, Scope of Application:

In the U-shaped container, there are positive and negative paddles.

Special proportion of the two paddles can be rectified with the

kind of material, quantity and the proportion of body. This mixer

has good effect on mixing viscosity or cohesion powder.

2, Characteristic:

a, Adjustable mixing speed can satisfy the rigorous demand of

mixing the materials with different physical property.

b, The rotation is under critical speed, which will reduce the

effect of fragmentation to the material(e.g. crystal particle).

c, Big area and short length paddle can move the wet material

better and cut the lumps, and won't let the material run with

agitator

d, The positive and negative paddles are set up at he same level,

forming a mixing environment of low power but high efficiency.

e, This mixer can add ribbon near the shaft for big size mixer, in order to help move the material in the middle

f, The paddle can push the material into the middle to discharge fully

3, Working Principle:

a, The horizontal axes make the materials move up and down.

b, The outer paddle gathering the material from sides to center and

the inner paddle pushing the material from center to sides.

c, Every screw makes the materials do axial and radial movement,

the materials do relative cyclical movement so to gain the

intensive mixings ends.

4, Specification:

| Type(m3) | Power(kw) | Rotate Speed(R/min) | (kg)(m3)/Batch | Dimension(mm) | Weight |

| WLH-0.3 | 3 | 41 | <240 | 2300×680×1060 | 750 |

| WLH-0.5 | 5.5 | 41 | <400 | 2900×780×1240 | 1000 |

| WLH-1 | 11 | 33 | <800 | 3200×1000×1400 | 1800 |

| WLH-2 | 15 | 33 | <1600 | 3860×1200×1650 | 2200 |

| WLH-3 | 18.5 | 33 | <2400 | 4320×1300×1900 | 3200 |

| WLH-4 | 22 | 28 | <3200 | 4600×1400×2000 | 4000 |

| WLH-5 | 37 | 28 | <4000 | 4850×1500×2020 | 4650 |

| WLH-6 | 37 | 22 | <4800 | 5400×1560×2200 | 6280 |

| WLH-8 | 45 | 22 | <6400 | 5100×1720×2420 | 8500 |

| WLH-10 | 55 | 19 | <8000 | 5610×1750×2360 | 9300 |

| WLH-15 | 90 | 17 | <12000 | 5820×2000×2900 | 11000 |

| WLH-20 | 110 | 11 | <16000 | 6060×2630×3160 | 13500 |

5, Seal:

The mixing result and the clean after-mixing environment depend on the sealing property. Our company provides various sealing devices according to difference of materials. The normal sealing structure is stuff seal and also called TEFLON seal. After using for a period, user(s) should fasten and enhance it. However, the dynamic seal has a long-time sealing effect and is especially fit for the powder, liquid.

6, Feeding inlet on the body cover:

Two types:

a, used in the whole mixing/ blending process: in order to connect the feeding device, we design the connecting mouth.

b, used in the manual feeding: in order to operate and clean inside of the body, we design feeding inlet(s) or door(s).

7, Discharging:

There is a discharging valve at the bottom of mixer body. When mixing different types of materials, we use flat discharging valve.

The operation of the discharging valve should be convenient and there are three types: manual, air driven and electricity driven.

The manual discharging is operated on the valve and the open extent is controlled by hand freely.

The air driven discharging valve, assembled with cylinder, work under the air pressure.

The electricity driven discharging valve works under control of electricity control box.

8, Extra function:

To realize the technicla of drying, cooling and keeping warm, the mixer can be added a jacket structure out of the tank. Hot water or steam or industrial oil can circulate int the jacket. Liquid filling system can be installed at the top cover, the different material of the atomized spray nozzle can realize the injecting of acid or alkali liquid, or water.

The tank and the agitator can be coated with other material like PE, PTFE, CARBIDE, etc. to realize the resistance of wear-out, acid/alkali, or explosion etc.

Single shaft paddle mixer : simple production line mixing system

|