| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Shengli |

| Model Number : | LDH/LHY |

| Certification : | CE and ISO |

| Price : | Negotiable |

| Supply Ability : | 200-300 SET PER MONTH |

| Delivery Time : | 1 MONTH |

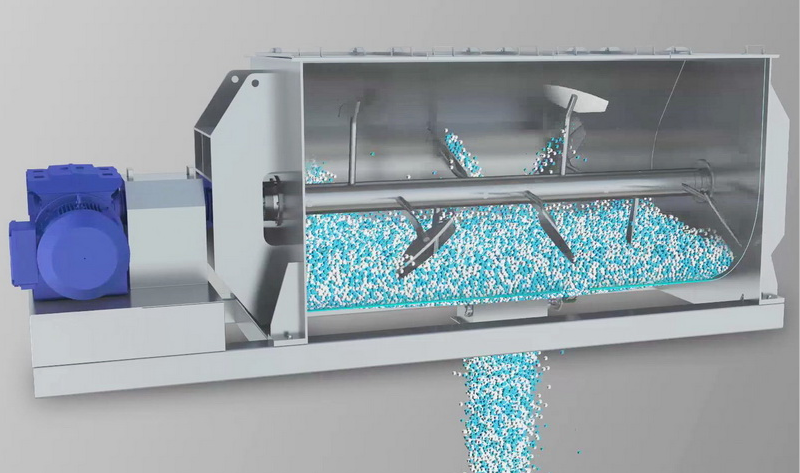

Batch Powder Blender , Horizontal Powder Ribbon Blender , Easy Maintenance

Introduction:

Powder mixer is widely used as powder blender, granule blender, and

small liquid additives in food blender, chemical blender, and

construction material blender.

It is particularly good at handling food additives, mortar,

fertilizing, sludge, plastic, and special building material,all

different kinds of powder or granule materials

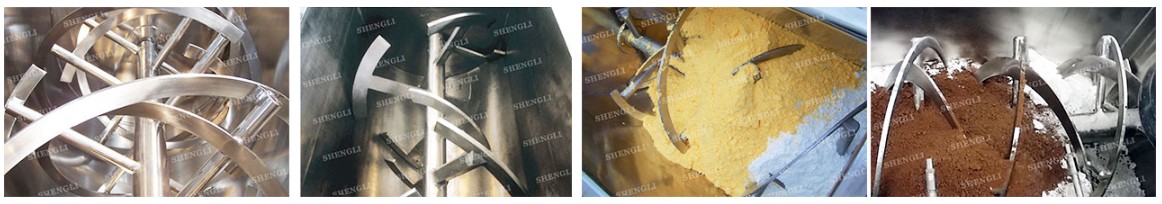

The agitator can be many different types, like plough agitator, ribbon agitator, paddle agitator etc.

Ploughshear mixer

| specification | LDH-0.3 | LDH-0.5 | LDH-1 | LDH-2 | LDH-3 | LDH-4 | LDH-6 | LDH-8 | LDH-10 | LDH-15 |

| working capacity(m³) | 0.18 | 0.3 | 0.6 | 1.2 | 1.8 | 2.4 | 3.6 | 4.8 | 6 | 9 |

| working capacity (KG) | 200 | 300 | 600 | 1200 | 1800 | 2500 | 3600 | 5000 | 6000 | 9000 |

| speed (R/min) | 130 | 130 | 85 | 63 | 63 | 42 | 42 | 33 | 33 | 28 |

| power (KW) | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 45 | 55 | 75 | 90 |

| weight | 550 | 800 | 1000 | 1800 | 2500 | 3500 | 4200 | 4800 | 5800 | 7000 |

| length | 2200 | 2700 | 3200 | 4100 | 4350 | 4700 | 5400 | 6500 | 5600 | 6000 |

| width | 900 | 980 | 1000 | 1250 | 1450 | 1500 | 1700 | 2200 | 2500 | 2800 |

| height | 900 | 1200 | 1350 | 1600 | 1800 | 1950 | 2300 | 2600 | 2900 | 3000 |

| specification | LHY-0.3 | LHY-0.5 | LHY-1 | LHY-2 | LHY-3 | LHY-4 | LHY-5 | LHY-6 | LHY-8 | LHY-10 | LHY-15 | LHY-20 | LHY-30 | |

| wrking capacity(m³) | 0.18 | 0.3 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.8 | 6 | 9 | 12 | 18 | |

| working capacity(kg) | 200 | 300 | 600 | 1200 | 1800 | 2500 | 3000 | 3600 | 4800 | 6000 | 9000 | 12000 | 15000 | |

| speed (r/min) | 62 | 62 | 49 | 33 | 33 | 27 | 27 | 27 | 22 | 14 | 14 | 14 | 12 | |

| power(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | |

| weight | 600 | 900 | 1200 | 2000 | 2500 | 3500 | 4000 | 4500 | 5000 | 6000 | 7500 | 10500 | 13000 | |

| Length | 2280 | 2670 | 3140 | 3860 | 4460 | 4950 | 5280 | 5530 | 5100 | 5610 | 5820 | 6300 | 7000 | |

| width | 680 | 780 | 980 | 1200 | 1300 | 1400 | 1550 | 1560 | 1720 | 1750 | 2000 | 2350 | 2600 | |

| Height | 880 | 1240 | 1400 | 1650 | 1700 | 2000 | 2100 | 2200 | 2500 | 2650 | 2900 | 3160 | 3350 |

Single shaft paddle mixer

| Type(m3) | Power(kw) | Rotate Speed(R/min) | (kg)(m3)/Batch | Dimension(mm) | Weight |

| WLH-0.3 | 3 | 41 | <240 | 2300×680×1060 | 750 |

| WLH-0.5 | 5.5 | 41 | <400 | 2900×780×1240 | 1000 |

| WLH-1 | 11 | 33 | <800 | 3200×1000×1400 | 1800 |

| WLH-2 | 15 | 33 | <1600 | 3860×1200×1650 | 2200 |

| WLH-3 | 18.5 | 33 | <2400 | 4320×1300×1900 | 3200 |

| WLH-4 | 22 | 28 | <3200 | 4600×1400×2000 | 4000 |

| WLH-5 | 37 | 28 | <4000 | 4850×1500×2020 | 4650 |

| WLH-6 | 37 | 22 | <4800 | 5400×1560×2200 | 6280 |

| WLH-8 | 45 | 22 | <6400 | 5100×1720×2420 | 8500 |

| WLH-10 | 55 | 19 | <8000 | 5610×1750×2360 | 9300 |

| WLH-15 | 90 | 17 | <12000 | 5820×2000×2900 | 11000 |

| WLH-20 | 110 | 11 | <16000 | 6060×2630×3160 | 13500 |

1. Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321;

besides, different material can also be used between the part contact with the raw material and the parts don’t contact with the raw material.

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

2. Reliable driven unit

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor.

Options for gearbox: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer.

Motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection

3. High efficiency mixing unit

1) Main shaft agitators: plow/ plough agitator together with high speed chopper.

2) The main ribbon agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

3) Double shaft paddle agitator coube be: two shafts blade, the special structure of paddle stirrers will cause materials have sudden zero gravity so as to satisfy even mixture of most materials with different physical properties

4. Excellent discharging unit

Standard valve for horizontal plough shear mixer is pneumatic

planar flap valve. When close the valve, the planar flap match the

mixing barrel perfectly

this makes no mixing dead zone and better mixing effect. The drive types of valve are Manual, pneumatic, and electric.

Valves for option: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc

5. Powerful auxiliary components

To realize the technicla of drying, cooling and keeping warm, the

mixer can be added a jacket structure out of the tank. Hot water or

steam or industrial oil can circulate int the jacket. Liquid

filling system can be installed at the top cover, the different

material of the atomized spray nozzle can realize the injecting of

acid or alkali liquid, or water.

The tank and the agitator can be coated with other material like PE, PTFE, CARBIDE, etc. to realize the resistance of wear-out, acid/alkali, or explosion etc.

batch powder blender, horizontal powder mixing machine,CE, easy maintenance,carbon steel mixer

Simple system of dry powder mixing equipment(powder blending line)

C1: using crane to hang jumbo bag material and feeding the mixer

C2: mufti-level platform, manual undo the bag, mixing and packing

with a bulk bag packer.

C3: simple mixer frame, feed the mixer manually with the help of a

folk lift.

C 4: using manual feeding platform, after mixing, screw conveyor

send the material to the storage silo, a packer under it.

C5: load the material manually on the ground,use vacuum feed to

transfer material into mixer, after mixing, pack with a bulk-bag

packer.

C6: multi-stage vacuum feeder, store it after mixing, then packing.

C7: multi-level operation platform, elevator sending to material

silo, mixing, storage, and then packing. Tower structure.

C 8: bulket elevator feeding, mixing, storage, and packing.

C9: vacuum feeding, mixing, storage, packing.

C10:Manual feeding, mixing, storage, packing

|